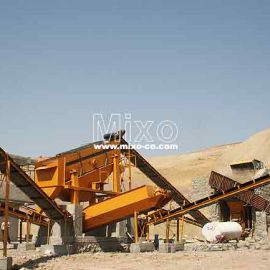

Vibrating screens are used for grading natural and broken materials in mountain and river mines.

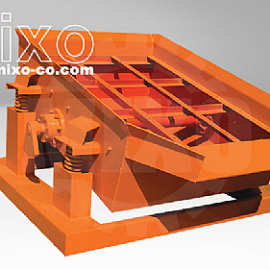

The main body of the screen is in the form of bolts and nuts, which provides a strong and suitable base for installing the screens, and in the event of erosion or damage to the body or screens, they can be replaced and repaired in the shortest time and at the lowest cost.

In order to optimally use the useful surface of the screen, vibrating screens are manufactured in different lengths, widths and classes.

In order to increase the percentage of grading separation, these screens are manufactured with a suitable slope for various materials, and if preliminary washing of the materials is required, it is also possible to install geyser systems on various types of screens.

Vibrating Screen Model: MSR01

| sarand vibratori | nam |

| MSR01 | madel |

| abead koli | |

| 7076 (mm) | tul |

| 3024 (mm) | arz |

| 4556 (mm) | ertafa |

| 6000×1500 (mm) | sath mafid sarand |

| 3×9 (m²) | mosahat sarand |

| 3 | taedad tabaghat |

| 150 (mm) | hadaksar saiz verodi |

| 1500 (mm) | dehaneh verodi |

| 1000 (r/min) | farkans larzeshi |

| 90~120 (t/h) | zarfit |

| 15 (HP) | ghodrat motor |

Show more

1,173 / 5,000

| Vibrating Screen | Name |

| MSR01 | Model |

| Overall Dimensions | |

| 7076 (mm) | Length |

| 3024 (mm) | Width |

| 4556 (mm) | Height |

| 6000×1500 (mm) | Useful screen surface |

| 3×9 (m²) | Screen area |

| 3 | Number of floors |

| 150 (mm) | Maximum input size |

| 1500 (mm) | Inlet |

| 1000 (r/min) | Vibration frequency |

| 90~120 (t/h) | Capacity |

| 15 (HP) | Motor power |