1- 4-piece feeder weighing materials with 8 pneumatic valves and digital weighing capability per batch of 6 m³ with 4 load cells and equipped with 3 vibrators with pneumatic box including 5 solenoid valves

2- Mother conveyor belt 23.5 meters long and 80 cm wide with simple three-ply thread rubber with 10 horsepower Chinese electric motor

3- 2-axis mixer (Twin shaft) with mixing capacity of 2 m³ per minute, with armor inside the boiler with Italian gearbox and 2 60 horsepower electric motors with pneumatic discharge valve and water piping into the mixer and equipped with structure

4- Cement scale with a capacity of 3000 kg with digital weighing system and equipped with 3 bending load cells

5- Central control room with unilite insulation and MDF floor with PVC flooring and roof and body covering

6- 1000 liter digital water meter With reset capability and display installed on the central control panel

7- 500 liter air compressor with 5.5 horsepower electric motor

8- 8 inch cement screw with 7.5 horsepower electric motor with 30 tons of cement per hour capacity, 1 unit

9- 8 inch cement screw with 15 horsepower self-propelled gearbox electric motor with 30 tons of cement per hour capacity, 1 unit

10- Central control panel with relevant electrical appliances and static body color with LG brand

11- Dry hopper with pneumatic valve

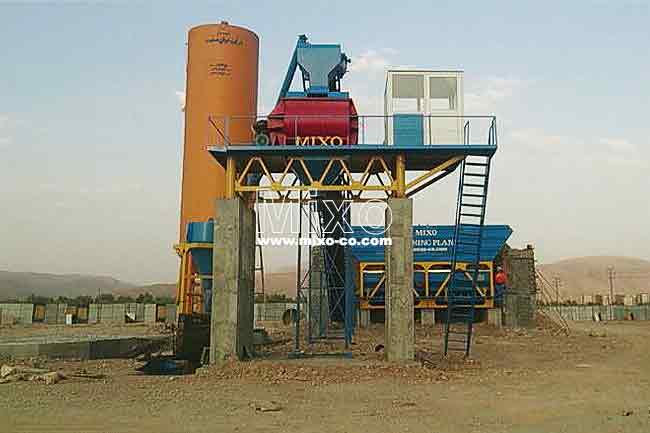

Stationary Concrete Batching Plant Model: MBT411

| beching polant (istgah markazi batan) | nam |

| MBT411 | madel |

| 90 (m³/h) | zarfit batan tar |

| 120 (m³/h) | zarfit batan khshk |

| 4×10 (m³) | hojam bargiri mosaleh |

| 6 (m³) | hadaksar hojam tozin mosaleh |

| 3000 (kg) | zarfit baskol siman |

| do mahvareh (tavin shoft) | no miksar |

| 2 (m³) | zarfit miksar batan |

| 2 (inch) | hadaghal ab moord niaz |

Show more

949 / 5,000

| Batching Plant (Central Concrete Station) | Name |

| MBT411 | Model |

| 90 (m³/h) | Wet Concrete Capacity |

| 120 (m³/h) | Concrete Capacity Dry |

| 4×10 (m³) | Material loading volume |

| 6 (m³) | Maximum material weighing volume |

| 3000 (kg) | Cement scale capacity |

| Twin shaft | Mixer type |

| 2 (m³) | Mixer capacity Concrete |

| 2 (inch) | Minimum water requirement |