Stationary Concrete Batching Plant Model: MBD160

| Batching Plant (Central Concrete Station) | Name |

| MBD160 | Model |

| 3×10 (m³) | Material Loading Volume |

| 1 (m³) | Maximum Material Weighing Volume |

| 1500 (kg) | Maximum cement weighing capacity |

| 4 (m) | Discharge height |

| 2 (inch) | Minimum water requirement |

| 30 (kw) | Electricity requirement |

| 16.7×20.7 (m) | Land dimensions required for installation |

1- 3-way material weighing feeder with 3 pneumatic valves and digital weighing capability per 1 m³ batch with 4 load cells and equipped with 2 vibrators with pneumatic box including 4 solenoid valves

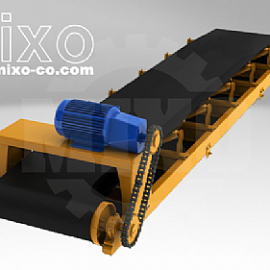

2- Mother conveyor belt 14.30 meters long and 80 cm wide with simple three-ply thread rubber with 7.5 horsepower electric motor

3- Cement scale with a capacity of 1500 kg with a digital weighing system and equipped with 3 bending load cells

4- Central control room with Unilite insulation and MDF floor with PVC flooring and roof and body covering

5- 1000 liter digital water meter with reset capability and display installed on the central control panel

6- 250 liter compressor with three-phase 2 horsepower electric motor

7- 8-inch cement screw with 7.5 horsepower electric motor, 6 meters long, with cement transfer capacity 30 tons per hour, 2 units

8- Central control panel with relevant electrical appliances and static body paint with LG brand