Aggregate weighing feeder is an important part of a concrete batching plant which is used to measure the amount of the needed ingredients.

One of the characteristics of this machine is its precise and digital weighing system. The weighing is done by a digital load cell with an exact mechanism according to the tonnage that is determined in its memory. With concrete performance so dependent on accurate measurement of aggregates, use of precise and digital aggregate weighing feeder has become a must in concrete and building industry nowadays.

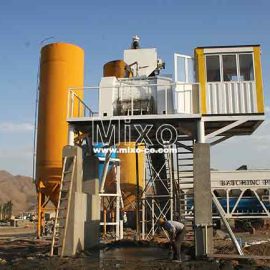

Mixo’s weighing feeders are manufactured using high grade raw material and on the base of the latest technologies and any changes can be applied on them according to customer’s order.

Depot capacities of these feeders are flexible from 10 to 500 ton on the based of customers’ needs.

Use of modern technology and experience in designing and manufacturing of these feeders give them excellent resistance against high pressure. The maintenance cost of these feeders is also very low and their keeping and service is very easy.